Decal Printing (Pad printing), transparent stickers, water decal, and hand-painting can all be used to display text and logo images on the surface of polyresin products. Here are the main differences between them:

Decal Printing / Pad Printing

Transparent Sticker

Water Decal

Hand-painting

=============================

Decal Printing / Pad Printing:

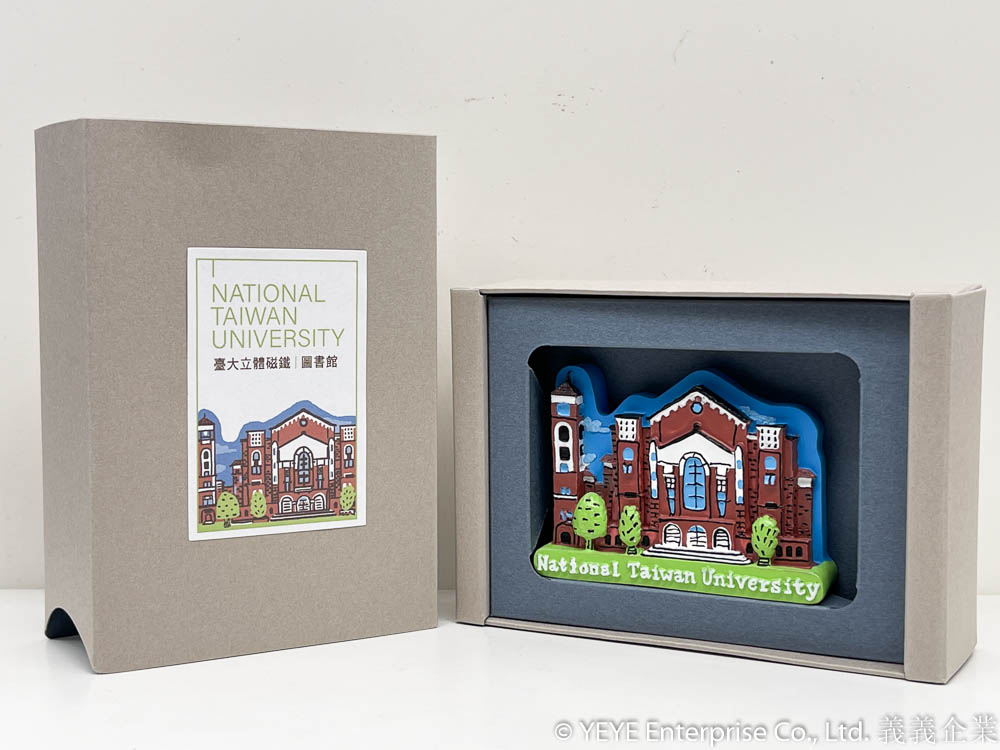

Decal printing is a printing technology that utilizes a highly flexible printing pad to apply ink onto complex-shaped products. It can be used on curved surfaces, irregular shapes, concave or convex surfaces, cylinders, spheres, and more. The ink dries quickly, enabling multi-color printing and fine details, making it one of the mainstream printing technologies today.

When decal printing is applied to polyresin products, it’s typically because customers have high-quality text requirements and are ordering a large quantity of products. The advantage of decal printing is that it doesn’t leave visible borders around the design. However, the disadvantage is that it requires sending the products to a printing facility, making it a more expensive option.

Transparent Stickers:

Transparent stickers involve printing text and designs on transparent or semi-transparent adhesive stickers that can be applied to various surfaces such as glass, plastic, and paper. This allows the design to seamlessly blend with the surface.

We recommend the use of transparent stickers when the design is intricate, contains small logos or text that cannot be hand-painted. Transparent stickers are cost-effective, easy to produce with a low risk of errors, but they have the drawback of reflecting light, and the sticker’s borders can be quite noticeable.

Nonetheless, if there is a strict requirement for text and logos, and does not want hand-painting involved, transparent stickers would be the primary production method.

Water Decal:

Water decal (water transfer decals or water slide stickers), involve printing the design on special paper. To apply them, you cut out the design along with the paper, soak it in water for a moment, and then gently slide the design onto the item you want to decorate.

Water decal stickers are easy to apply and don’t require special skills. The designs are usually quite durable, resistant to fading, peeling, and don’t produce reflections. They are typically used for decorations and patterns on surfaces like nail art, phone cases, ceramics, glass, wood, plastic, and more.

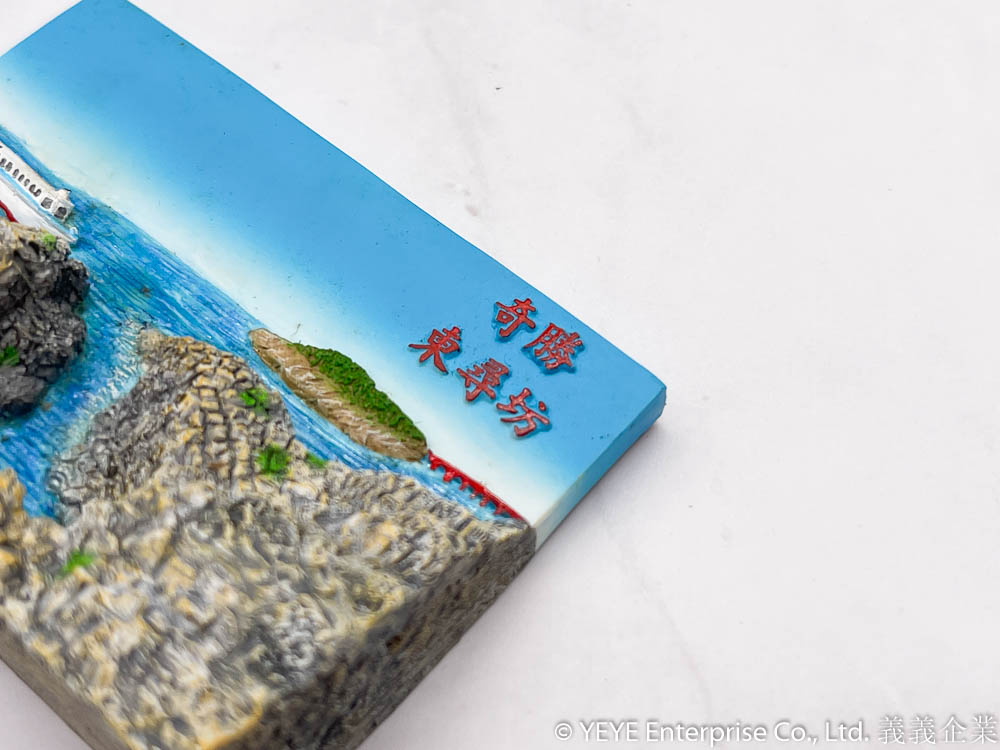

Hand-painting:

Compared to decal printing, transparent stickers, and water decals, hand painting is our most commonly used method during production.

Apart from not incurring additional costs, hand-painted text appears 3D, enhancing the product’s quality and adding warmth. When text is hand-painted, there is no need to worry about it not working well on curved surfaces. These texts or designs are created during the sculpting phase and painted during the hand-painting phase.

However, because hand-painting is a manual process, it cannot be 100% perfect and accurate, and there may be some variations to a greater or lesser degree. If you have a highly detailed logo or require precise color accuracy, it’s advisable to use printing or sticker methods to achieve the desired result.