Thank you to the Nankunshen for granting permission to share the product manufacturing process.

If you are interested in these 6 products, you can purchase them through the following link: Shopee & HW夯物。

======================

Thanks to the advantage to produce small quantities of diverse items, polyresin is always an excellent option for making small size 3D figurines. They can range in size from 3cm to 30cm and can be created as a single, unified piece. If necessary, they can also be produced as separate parts and assembled later.

Figurines larger than 30cm typically involve cost-cutting measures or the use of materials like plaster, especially for garden and landscape decorations. Additionally, these larger figurines are often hollowed out to reduce weight, as a solid 30-centimeter figurine can weigh over 5kgs.

Small size figurines has always been a primary product line for our company, and it’s our specialty. Fine painting details are well within our capabilities. This time, we were requested to create six figurines, each one is measuring approximately 6-7cm: representing The Five Royal Lords (Lord Lee 李府, Lord Chih 池府, Lord Wu 吳府, Lord Jhu 朱府, Lord Fan范府) and The Child Spirit萬善爺.

==================================

There are several challenges when making these figurines:

1) The designs featured many intricately detailed and visually appealing protrusions. However, this made the white body easy to breakage during molding. We had to carefully adjust the angles during this process to prevent any breakage.

2) These figurines featured a wide array of colors, creating a vibrant and multicolored appearance. We made every effort to present all the patterns and designs.

3) After painting, a layer of clear gloss varnish was applied. Varnish enhanced the figurines’ appearance, giving them a glossy finish. However, it also made any surface imperfections more noticeable. Therefore, careful surface refinement was crucial during production. The drying time for the gloss varnish was relatively long, and it was susceptible to dust and dirty during drying process.

We crafted the clay mold based on design artwork. Once the clay mold was completed, we took photos from different angles to got confirmation with the client. If the clay mold received approval, we proceeded to the silicon mold making and production of painted samples.

It’s important to note that design modifications are possible during clay mold stage. However, once the mold is made, any changes to the design become impractical, as the clay mold may be damaged in this process.

These figurines are 3D, and some feature hollow spaces within the design. For example, the figurine of Lord Lee 李府 has gaps between the legs, and hollow areas in the accessories and headgear. After demolding, these intricately detailed areas with hollow spaces require meticulous attention to the mold’s parting lines.

After confirming the clay molds, we took photos from different angles and provide them to the client for design approval. If there are no issues, we finish sampling stage.

At this point, we provide 2pcs of sample for the client to keep, and these samples serve as the reference for color matching during mass production.

It’s important to note that color modifications are possible at this stage, but any changes to the design are no longer feasible.

For these six designs, the most challenging parts to create are the accessories of the Lord Lee 李府 and Lord Fan 范府 figurines. Because these accessories do not have full contact with the figurines; instead, they consist of intricate and delicate structures with openings.

Compared to the previous two designs, the Lord Wu 吳府 and Lord Jhu 朱府 figurines have slightly thicker protruding parts. For example, the Lord Wu 吳府Fu holds a compass, and the Lord Jhu has more robust fingers and arms. As a result, these figures experience fewer damages during the manufacturing process.

The design artwork only included rough outlines for the backside. Our sculpting team added the necessary details, and the coloring part was done by our sample coloring staff. These samples were provided to the client for their approval.

At this point, all six figurines are completed.

Typically, during the initial production run, it takes a few extra days to let production line staff to find quick and low-damage demolding method. This includes refining the mold-making process, optimizing the angle and technique for removing the figurines from molds. The painting staff also requires some time to practice since they use various coloring tools. Discovering efficient coloring methods helps maintain both speed and quality in production.

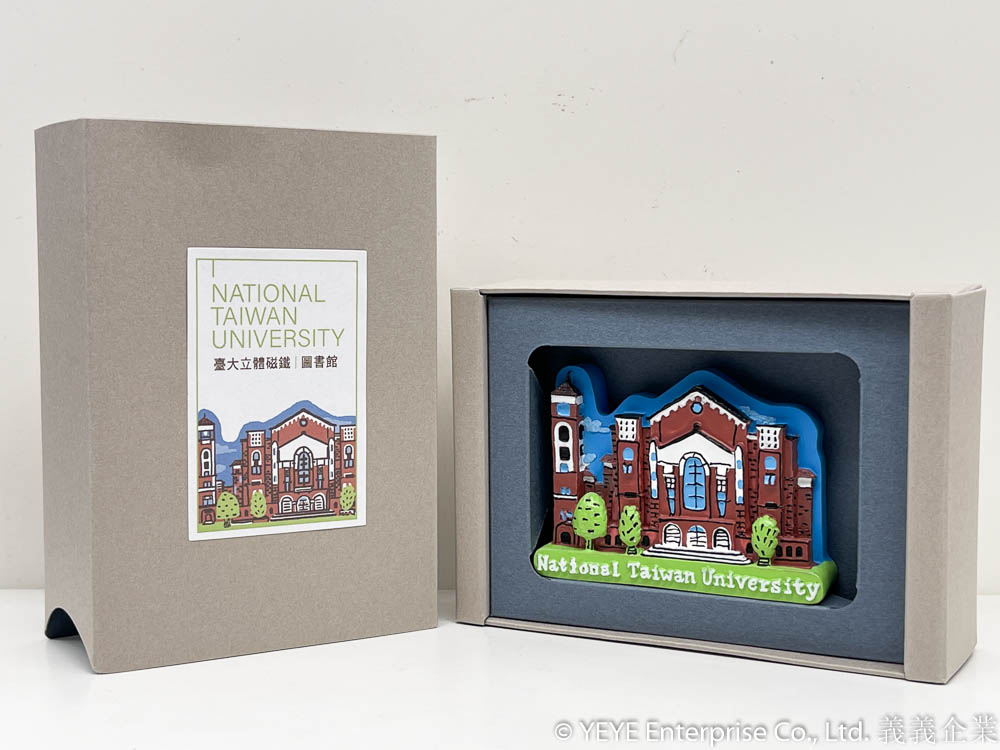

Regarding packaging, this particular client provided design drawings and entrusted us with the printing.

Upon receiving the products, the client can simply open the carton and place the items on the shelves without any additional processing.