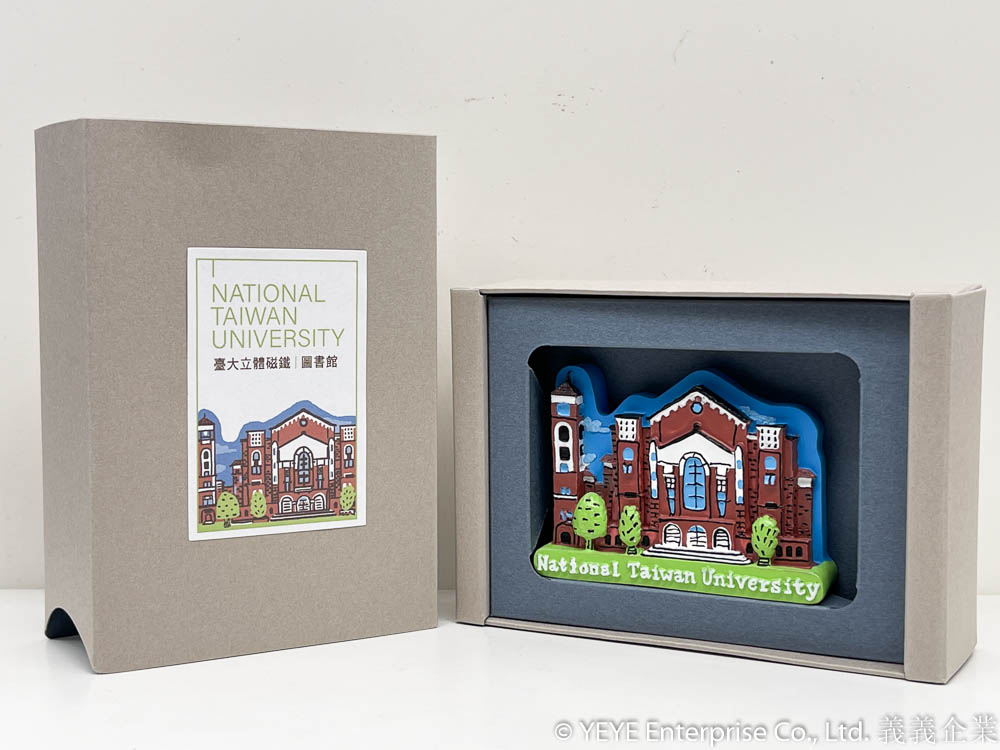

Compared to plastic injection, which requires machine injection using steel molds and often has a minimum order quantity (MOQ) of 5,000 or 10,000 pieces to be cost-effective, polyresin products have lower MOQ requirements, typically around 500 or 1,000 pieces.”

We typically quotes based on a MOQ of 1,000 pieces. However, if customer requires a lower production quantity, we can discuss this further in detail.

For souvenir and tourism industry, offering a variety of products in small quantities is important, as it allows for a diverse display to cater to the different preferences of each visitor. However, even 1,000 pieces of the same product might be too many for some customers. In such cases, we recommend painting the same style with different colors to create a more diverse product range.”

For example, in the production of 2,000 pieces of a snow jacket, the jackets come in 4 different colors: 500 in red, 500 in green, 500 in yellow, and 500 in blue. Since the mold is the same (the same style), the differentiation is achieved through 4 different colors during painting, allowing for a greater variety of product offerings.

All of the above are the same style, with different colors in the painting, giving them a variety of variations.

In some cases, only a partial change is required, but most of the patterns remain the same, while the painting needs to be done differently. This can still be produced, but it would require creating two sets of silicon molds.

For example, in this model above, the entire product is the same except for the text at the bottom, which says “黃虎將軍” and “黑虎將軍”. This kind of variation should be communicated during the sampling stage, so that we can create both versions during sample process.