We were told from many customers that after some time, the magnets on refrigerator magnets detach from the polyresin body, especially when the magnet has been stationary for several years or placed on surfaces with higher temperatures like a refrigerator, oven, or computer casing. Additionally, magnets may deteriorate and break apart after years.

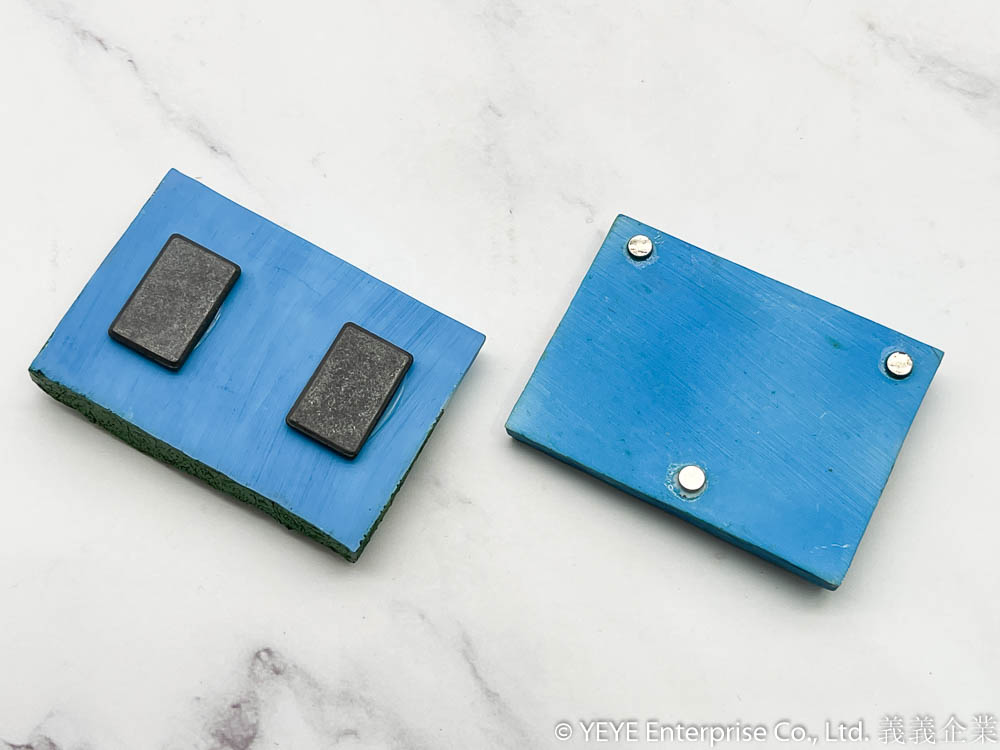

The traditional way is using adhesive to attach magnet to the back of polyresin body. We’ve used various types of magnets, including the most common ferrite magnets (black, large block shape), soft magnets (a sheet of soft magnet), and powerful neodymium magnets (NdFeB magnets).

However, regardless of the type of magnet used, issues like magnet detachment and deterioration can still occur. To address these problems, we’ve experimented with different approaches, such as testing various brands of adhesives like hot glue, instant glue, AB glue, etc. We’ve also tried applying protective coatings to the magnet surface to prolong its lifespan.

Despite these efforts to find better adhesives and some improvements in the situation, as long as magnets are attached using adhesive, these issues cannot be 100% eliminated because chemical adhesives deteriorate, and the magnets themselves degrade over time.

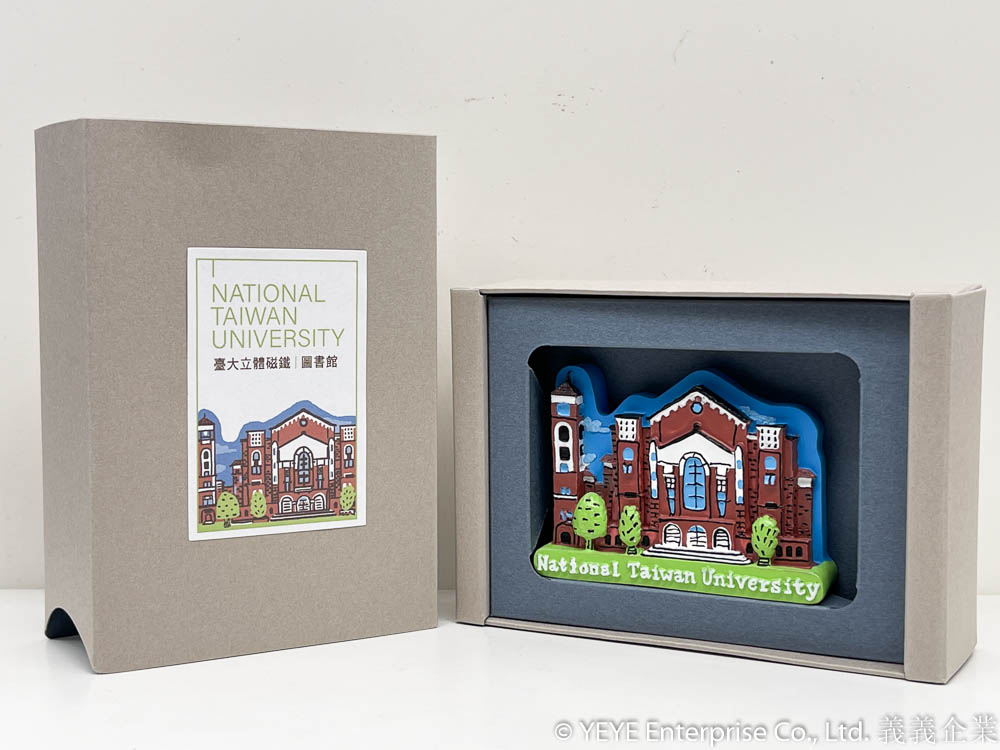

In this case, our company has completely shifted to using buried magnets. This not only eliminates concerns about magnets detaching but also maintain magnetic strength.

With buried magnets, magnets will never detach due to adhesive deterioration, and the appearance is also more attractive.

With buried magnets, there are no gaps between the magnet and the metal surface it adheres to. Magnets attached to walls or cabinets won’t fall off with slight impacts, and their magnetic force is stronger and more stable.

The magnet surface no longer requires a protective coating to prevent weathering. It can directly adhere to metal surfaces, ensuring that the magnet’s strength is not reduced by coatings.