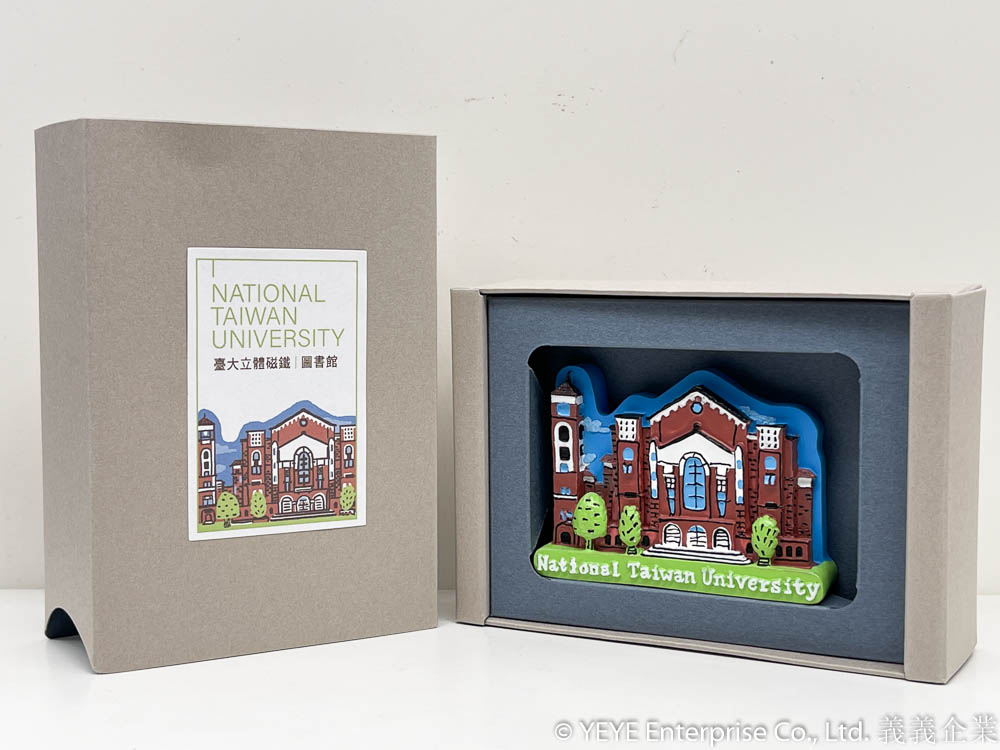

Poly, Polystone, Polyresin, and Resin, these terms refer to the materials used in the products manufactured by us, Yeye Company.

The first step in production is to mix polyresin with stone powder. Polyresin is a type of low-temperature resin. It is replicated using a silicon mold without the need for metal molds or injection machines, making the production process relatively simple.

Polyresin products are crafted using silicon molds, allowing for low-temperature shaping, cost-effective molds, and a low minimum production quantity. This method is well-suited for producing a variety of products in small quantities.

The advantages are:

- Cost-Effective Material: The material is relatively inexpensive.

- Heat Resistance: Resistant to deterioration when exposed to heat; it has good heat resistance.

- High Hardness: Exhibits a high level of hardness.

- High Detailing Capability: Demonstrates a high level of detail in reproducing various surface textures.

- Long Lifespan: Longer lifespan with resistance to damage; it does not easily deform or discolor, making it well-preserved over time.

The disadvantages are:

- Increased Weight: The addition of stone powder increases the weight of the finished product, making transportation and handling less convenient.

- Lack of Flexibility: The material lacks elasticity, making it prone to fracture or break upon impact. Additionally, it is not easily processed or cut.