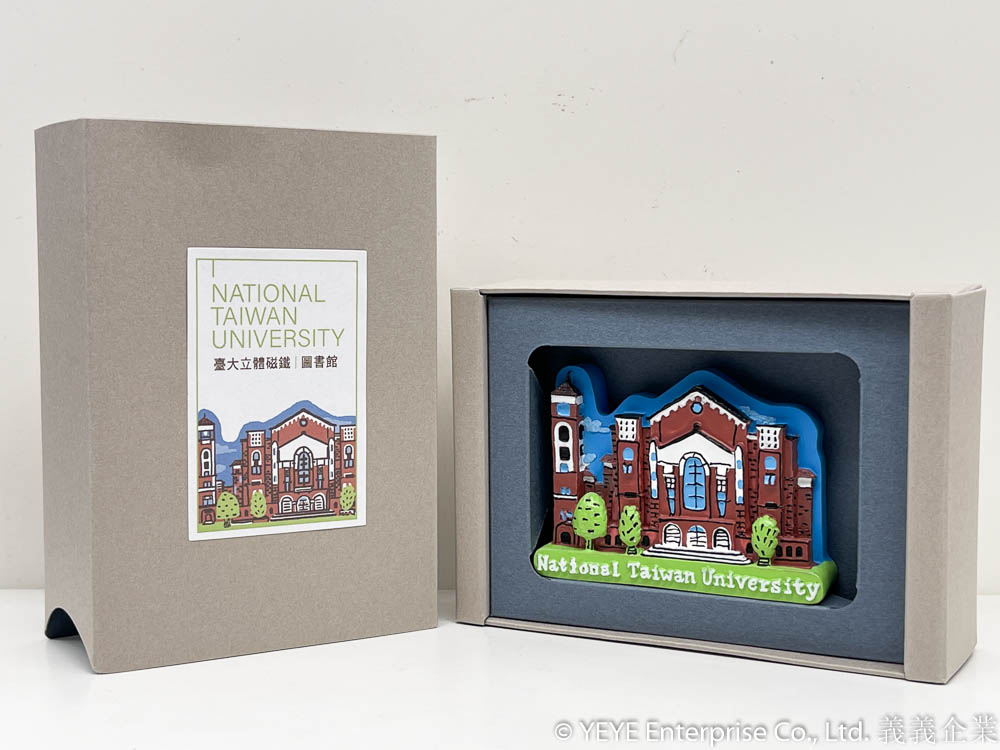

We were asked by clients very often: How can we ensure that painting colors remain consistent in mass production production, meaning every batch of 1,000 pieces or even more? How do we guarantee the quality of the paintwork?

Our production principle is “Same item, same factory, same batch of paint, few people for painting.”

The benefits of this approach are as follows:

1) Quality Control: It allows for effective control of paint quality, ensuring uniformity in all areas that require painting.

2) Consistent Color: The color of the entire batch remains consistent. Individual variations in brush pressure, resulting in variations in color depth, are eliminated.

3) Skilled Workforce: Painting staff become skilled at painting a single model, leading to increased proficiency and, consequently, higher production speeds.

Furthermore, “The paint colors prepared for the same batch of production will be consistent, but there may be variations in color between different batches.”

For example, when placing an order in January of this year, all the paints used are mixed by the color department this time.

When repeating order in January of next year, all the paints are freshly mixed again, rather than using previous year’s paints.

This is because it’s impractical to keep all the paints. Even if they were kept, exposure to air or prolonged storage can cause them to deteriorate and change in color.

When these two batches are placed side by side, there might be slight color differences.

With the exception of white, black, or specially requested colors from paint manufacturers, the vast majority of paints are mixed at our factory.

Therefore, it’s not possible to completely eliminate color variations between different batches.

However, within the same batch, colors will be consistent because they are mixed and applied in the same process.