In the sample production process (link), we introduce how we transform images into polyresin products.

We employ clay (oil-based) to create clay models, and the greatest advantage of clay is the rapid modeling. Skilled staff can complete clay models in a short amount of time. Clay models can achieve intricate styles such as undercuts and internal details, allowing for the creation of a variety of different shapes.

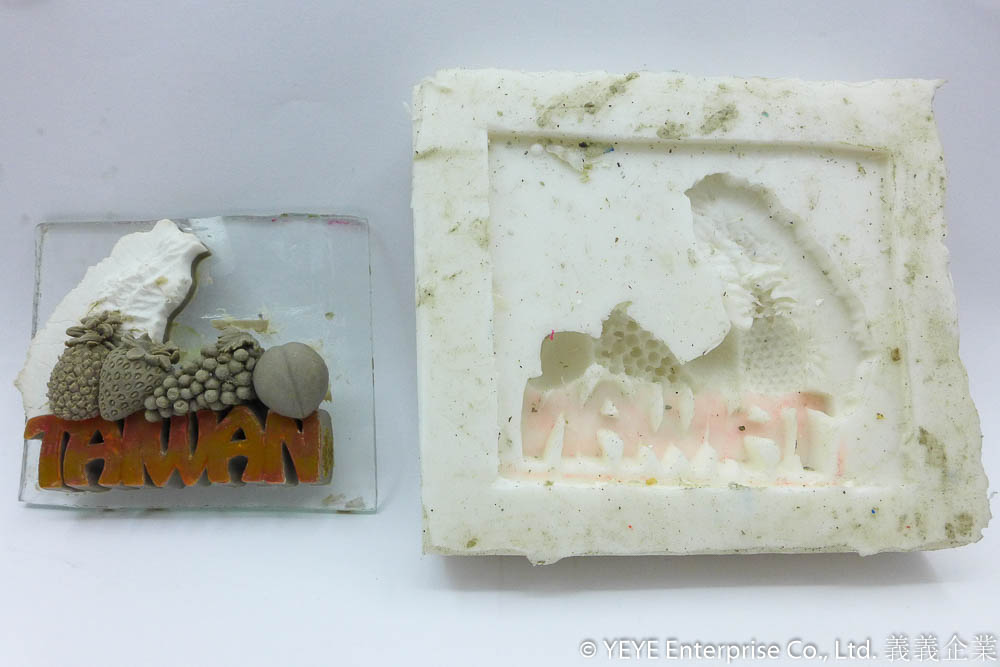

We use clay models to create silicon mold, and the clay models are typically damaged in this process. The clay tends to break and deform when removing it from the mold during demolding.

Left: clay mold / Right: silicone mold.

After pouring polyresin material into silicon mold, we can obtain a replicated white body (white form).

Due to the shrinkage of silicone molds, the white body’s dimensions may be 1-2% smaller than original clay model.

After the white body has been refined, the painting staff will process hand-painting.

===============================

In addition to using clay mold to create silicon molds, if you already have a sample and want to reproduce it, you can directly create a mold for mass production. This approach is called “reproduction molding.” The reproduction molding process is streamlined, resulting in a reduction of the sampling time by several days.

However, when reproducing mass-produced items from a sample through reproduction molding, the dimensions may change, typically being 1-3% smaller than the original sample. If precise dimensions are critical, please inform us before sampling process to avoid any discrepancies between the produced dimensions and your expectations.

===============================

Additional Reading: sample production process (link)