Polishing and grinding are necessary for treating the surface of polyresin products in order to enhance their appearance and texture.

Polyresin materials are in liquid form and require stirring during shaping process, which introduces air and results in the formation of air bubbles, making the surface appear granular, rough, uneven, or irregular.

These air bubbles or rough surfaces not only detract from the aesthetics but also impact subsequent coloring. When painted or coated, they become even more pronounced.

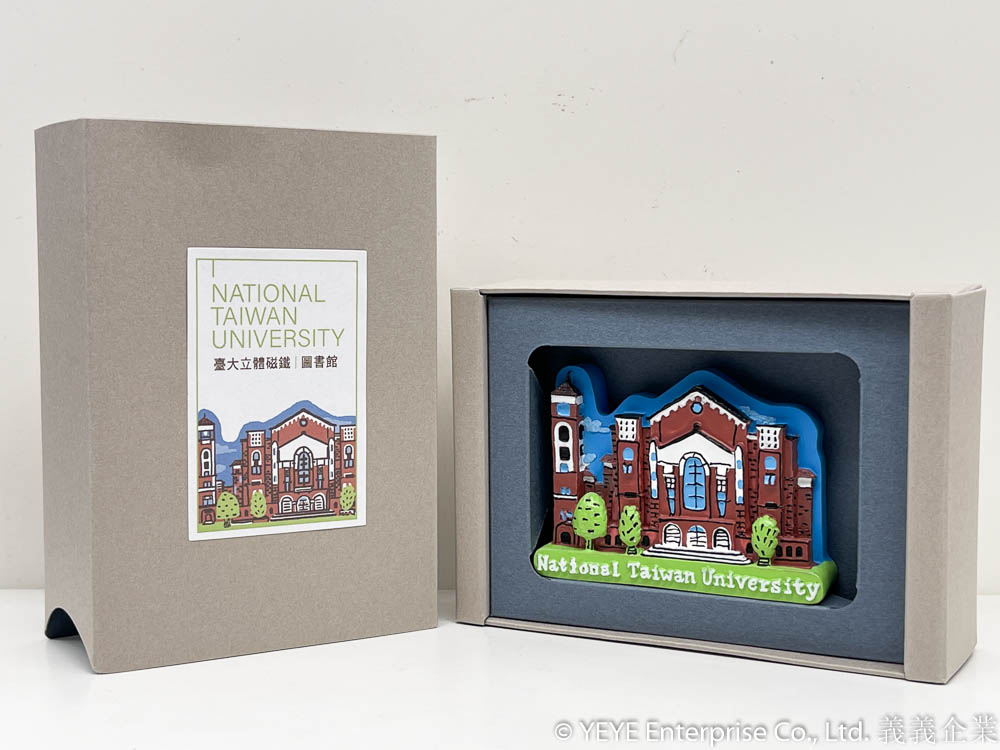

After processing, the surface will appear smoother and more uniform, giving the product a refined look and enabling the creation of a glossy finish.

Different products and application scenarios may require varying degrees and methods of grinding and polishing. Whether it’s large surfaces, small areas, flat or curved surfaces, crevices, or grooves, all need to be processed to achieve smoothness.

By using different grades of sandpaper and various tools like automatic buffing machines, grinding machines, finishing pens, and rolling machines, the polishing process can be expedited. If the items to be processed have sharp edges that are prone to breakage or have numerous crevices and gaps, manual polishing by workers might be necessary.